Machining Services

CAD Programming Services

Pegen utilizes a combination of Solidworks and GibbsCam 3D CAD software to analyze parts for manufacturability. We are able to analyze client provided models in many different formats including (dxf, dwg, stp, step, igs, iges, slddrw, sldprt and sldasm). The flexibility in file types we accept eliminates the need for clients to modify their files for manufacturing purposes – leaving more time to engineer and perfect designs.

We have 3 dedicated Machinist/Programmers on staff to ensure every model is reviewed, programmed, setup and manufactured to client specifications by our team of machinists. Whether your projects are simple or complex, we ensure they are treated with the highest care and attention to detail.

Machining Processes

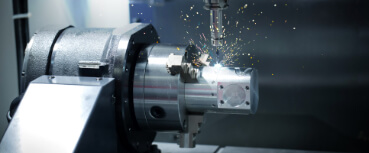

CNC Milling

Our CNC milling processes utilize 3, 4 and 5 axis machining techniques. We use a mix of FEELER, HURCO and HAAS machining centers to complete your parts and assemblies. We are able to hold tolerances up to 0.0004” (0.01mm) for precision parts and have the ability to machine complex features without having to use multiple setups. This increases flexibility in manufacturability and reduces overall time to complete parts.

Conventional Milling

We firmly believe that there is still a place for conventional machining. It serves the ‘one off’ prototype market by ensuring we produce parts quickly and efficiently. We are able to hold tolerances of 0.001” (0.025mm) utilizing conventional milling. This manufacturing option is also highly desirable for second operations when required. This type of machining center is also particularly useful for clients who have time sensitive needs or a ‘‘line down’ situation where repair parts are required urgently.

We operate a line of 4 Bridgeport style Lilian 5VH machines with Accurite MILPWR 3 axis controllers that are ready to service your needs at a moment’s notice.

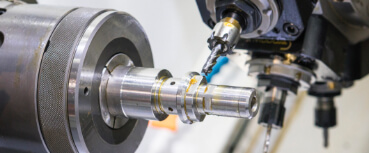

CNC turning

Our CNC turning centers include both conventional 2 axis tool room lathes as well as a multi axis, two spindle CNC turning Center with Live Tooling. We are able to hold 0.0004” (0.01mm) tolerances on all turned parts.

Our live center is also able to mill features such as holes, slots and grooves that are not normally achievable during standard turning processes. This reduces the time to make parts and limits additional machining setups. Our turning centres are set up for both prototyping and low to medium volume production runs.

Equipment

To better understand what types of machining centres make your parts and assemblies, please scroll through the common machining centres your parts will be manufactured on. For a complete listing of our equipment, please contact us.

Value-Added Services

Pegen offers a wide range of value-added services for both its

Machining and Sheet Metal operations. Learn more.

Don’t know if it

can be made?

We do!