Fabrication

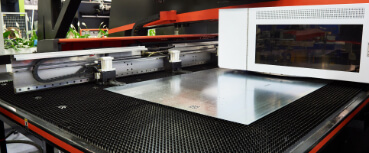

CNC Punching

Pegen utilizes the newest and most advanced punching technology available today. We are able to hold tolerances of 0.004”(0.1mm) on punching operations on material thicknesses ranging from 0.030” to 0.125”. Our partnership with Amada Canada has enabled us to enhance our capabilities and quality for all sheet metal related projects.

We currently use Hexagon’s Radan programming software to analyze client supplied models and wire frames. This ensures an optimal programming solution is created to produce parts in a timely and efficient manner.

We can accommodate prototyping, short run and volume run production based on your requirements.

Part Forming

Our forming department is equipped with 2 Brake Presses of 65 and 135 tons respectively. CNC back gauges are utilized to ensure parts are made to client specifications and we can form parts up to 10 feet in length. As sheet metal has inherent variability in design and material composition, we aim to manufacture all formed parts to within 0.010” of stated drawing dimensions. Where more precision is required, we work closely with our clients to ensure they receive parts that meet their functional needs.

Welding

Pegen offers a complete range of welding services for weldments up to 1000lbs (454kg). We can accommodate requests in steel, stainless steel and aluminum. We employ 2 full time CWB welders who are fully qualified in TiG and MiG welding. We also have experience in soldering of small fixtures.

Equipment

To better understand what types a tooling centers make your parts and assemblies, please scroll through our listing below

Value-Added Services

Pegen offers a wide range of value-added services for both its

Machining and Sheet Metal operations. Learn more.

Form your designs

into parts today!