Pegen offers a wide range of value-added services for both its

Machining and Sheet Metal operations. We have:

A fully integrated

finishing department

A fully integrated assembly

department for mechanical

assembly of machined and

fabricated parts

An approved network of

subcontracting partners for your

specific coating needs

Finishing Options Available

Finishing options - pre coating

Each part that is manufactured at Pegen goes through a standardized finishing process. Depending on the application of your parts, they can be finished in many different ways.

- Natural – we will break edges and deburr –

visible tooling marks remain - Orbital Sanding – used for larger parts to remove tooling marks

- Blasting – we will media blast your parts for a uniform finish (note parts with crucial tolerancing cannot be blasted)

- Tumbling – we will tumble you parts, leaving them with a matte finish

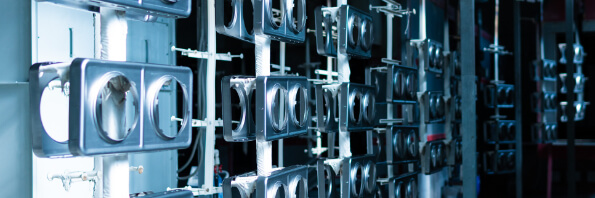

Coatings

We operate a fully compliant Military specification Chemical conversion line (commonly referred to as Iridite, Oakite or a Chemical film). Our tanks can accommodate parts and assemblies of up to 30” in length or width.

In house Specifications offered

- Type II, ROHS (clear)

– Class 1A – for maximum protection against corrosion

– Class 3 – For maximum protection against corrosion

where low electrical resistance is required

Through our approved subcontractors network we offer the following general coating processes:

Anodizing, Chemical Conversion Coating, Zinc Plating, Nickel, Gold, Silver and Tin Plating, Passivation and Electropolishing, Specialty coatings (Nedox, Teflon), Heat Treatment, Painting (Powder and Wet)

As there are many different coatings and specifications available, please contact us to discuss your specific needs.

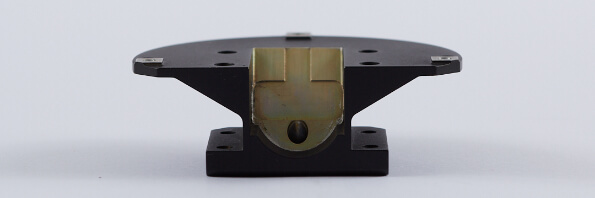

Assembly

Our assembly department is able to accommodate many different types of assembly activities including

- Dowel pin installation into jigs and fixtures

- Helicoil insertion and installation

- PEM installation

- Mechanical assembly of machined and Fabricated parts

Manufacturing Materials

Choose from many different types of metals and plastics for prototyping or production, or supply your own!

It’s time for

your concepts to

become reality